Biocomposites are materials that are easy to manufacture and environmentally friendly. Sugar palm fibre (SPF) is considered to be an emerging reinforcement candidate that could provide improved mechanical stiffness and strength to the biocomposites. Numerous studies have been recently conducted on sugar palm biocomposites to evaluate their physical, mechanical and thermal properties in various conditions. Sugar palm biocomposites are currently limited to the applications of traditional household products despite their good thermal stability as a prospective substitute candidate for synthetic fibres. Thus, thermal analysis methods such as TGA and DTG are functioned to determine the thermal properties of single fibre sugar palm composites (SPCs) in thermoset and thermoplastic matrix as well as hybrid SPCs. The biocomposites showed a remarkable change considering thermal stability by varying the individual fibre compositions and surface treatments and adding fillers and coupling agents. However, literature that summarises the thermal properties of sugar palm biocomposites is unavailable. Particularly, this comprehensive review paper aims to guide all composite engineers, designers, manufacturers and users on the selection of suitable biopolymers for sugar palm biocomposites for thermal applications, such as heat shields and engine components.

1. Introduction

Lignocellulosic fibres are widely known in industrial manufacturers due to their versatility and wide availability and their role in fulfilling the concept of sustainability [1], [2]. The lignocellulosic fibre is applied in polymer compounds to form biocomposites. These fibres are harvested from crop wastes, such as pineapple leaf, sugar palm fibres (SPFs), coconut sheath and kenaf stem [3]. A variety of cellulosic fibres, such as kenaf [4], flax [5], sugar palm [6] and pineapple leaf [7], have generally been used for various composite engineering applications. The escalation in the production of lignocellulosic fibre composites is observed during such applications because of their availability and abundant advantages, especially on eco-friendliness towards the environment. Moreover, other advantages of lignocellulosic fibre composites include thermal insulation properties, good formability, cheap cost and renewable and sufficient energy requirements [8], [9], [10]. Considering chemical composition, lignocellulosic fibres comprise cellulose as their cell structure and co-exist with hemicelluloses, lignin, pectin, waxes and water-soluble substances [11]. However, the chemical compositions may vary from one plant to another even for similar species due to the high dependence on fibre extraction techniques, geographical factors, plant growth conditions, height and parts of the plant [12], [13], [14], [15].

One of the drawbacks of lignocellulosic fibres lies in their hydrophilic properties, which elevated their moisture absorption rate, subsequently reducing their bonding wettability with hydrophobic polymer resin. Thus, this condition led to non-uniformity, lack of thermal stability and limited mechanical strength, which also contributed to unfavourable properties relative to polymer composites [16], [17], [18], [19]. Various treatments, including physical and chemical techniques, are introduced to solve this issue and alter its compatibility with polymer to form effective composites. The treated lignocellulosic fibres would have rough surfaces, which would allow additional activated locations in fibre topography [20], [21]. Subsequently, such a treatment would form a strong chemical bonding between the interfaces of two phases with a good network linkage and improve its applications for wide engineering applications [22], [23], [24], [25].

Amongst lignocellulosic fibres, Arenga pinnata, which is usually known as sugar palm, possess promising behaviors for application as reinforcement in composites. SPFs are abundantly available in Malaysia, Indonesia and other south Asian countries. SPFs are one of the progressive lignocellulosic fibres in composite industries, which contribute to the advancement of green technology in packaging, food container and furniture [26], [27], [28], [29], [30]. Therefore, the selection of SPF from its tree is one of the vital factors considered to realise good thermal properties that are useful for food packaging and automobile industries. Ishak et al. [31] revealed that 1 m SPFs display consistently higher thermal stability than the fibre of 3 to 15 m. This finding is attributed to the high silica content for fibre at 1 m due to the high ash content. Thus, the promising fibre location in sugar palm trees is at 1 m from the ground. Moreover, fibres obtained at the dead palm frond region for application as reinforcing fibre in polymeric composite should be avoided.

The currently available review articles are based on the thermal properties of general polymers, synthetic composites and biocomposites with various fibre reinforcement methods. These reviews are inadequate and slightly informative, especially considering sugar palm lignocellulosic fibre reinforced polymer composites. Subsequently, this review article narrowed the results of thermal analysis techniques, such as TGA and DTG, to evaluate various sugar palm lignocellulosic fibre biocomposites. This comprehensive review also updates the research works achieved in recent times on the front of thermal properties of SPF and its biocomposites for different applications. Moreover, this review highlighted the thermal properties of sugar palm biocomposites with several factors, including the polymer resins (e.g., thermoplastic, thermosets and biopolymer), fibre loading, fibre sequence with the use of two or more fibres and fibre modifications. Sugar palm biocomposites will eventually substitute petroleum-based composite materials, which will promote a green environment and lower carbon emission in the future.

2. Sugar palm (A. pinnata)

Sugar palm is known as A. pinnata, which is one of the uprising lignocellulosic fibres from the Palmae tree family. The sugar palm tree (A. pinnata) belongs to the Palmae family, which has around 181 genera and over 2600 species worldwide [32]. This plant is often found in hot, humid areas of the South and Southeast Asian tropics. The sugar palm has been the most economical plant in Asia, and its geographical distribution covers the Indo-Malay archipelago, which includes South East Asian nations, such as the Philippines, Indonesia and Malaysia [33]. The sugar palm plant is a physically tall palm tree with decorative trunk fibres and long shape leaves. A new way to cultivate sugar palm plants efficiently has been recently developed. The first sugar palm factory has been newly constructed around the globe in Tomohon, Indonesia [34]. As by-products, SPFs will be highly available with the growth of the sugar palm plantation. Sugar palm also has the widest variety of applications, making it a multifunctional palm species. The SPF has many applications and uses, such as the manufacturing of brooms, paintbrushes, septic tank base filters, clear water filters, door mates, carpets and ropes for sea cordage, in certain areas in Indonesia [35]. Sugar palm was also used in sugar, sago, wine, alcohol, fibre, thatch and many other products. Ilyas et al. [36] stated that distinguishing lignin and cellulose components in SPFs by implementing the isolation process is possible. The isolation process of cellulose and lignin can be conducted by immersion SPF in a 60 wt% concentrated sulphuric acid solution. Additionally, the plant can produce bioethanol, which can function as alternative fuel [37], [38]. This condition is due to the higher alcohol production capability of the sugar palm plant compared with sugarcane, sweet sorghum and cassava.

2.1. Physical and mechanical characteristics of sugar palm fibre (SPF)

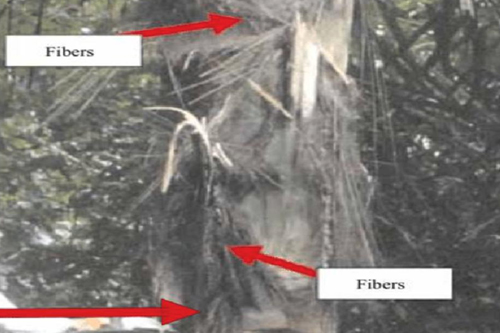

Sugar palm or black-fibre palm is popularly known in Malaysia as pokok kabung or enau. Fig. 1 shows SPFs wrapped around the tree trunk from top to bottom. This cellulosic fibre has been extensively applied in a wide range of applications, especially household products, due to its durability and strength [31]. The SPF is black and is also locally known as ijuk fibre; it is commonly used for manufacturing ropes, brushes, roofing, brooms and other handicraft products [33]. One of the main advantages of SPF lies in its durability and capability to withstand a long life because it remains unaffected by moisture and heat compared with coir fibre. Mukhtar et al. [35] indicated that the trunk of SPF is solitary, straight and generally 15 to 20 m in height with a diameter of up to 65 cm, with large leaves that can reach 6 m in length. The black fibrous hair that covers the trunk is known as ijuk or injuk. SPFs, which mostly have lignocellulosic and multicellular fibres, are currently regarded as waste products from sugar palm agriculture [39], [40]. These agro-residue fibres have a high cellulose content and can be utilised for industrial applications, such as converting wastes into high-value biomaterial products, and also have considerable potential as reinforcement for biocomposite products [41]. Fig. 2 displays the preparation and extraction process of SPF from sugar palm tree.

Read More...

Authors - Asyraf M.R.M., Ishak M.R., Norrrahim M.N.F., Nurazzi N.M., Shazleen S.S., Ilyas R.A., Rafidah M., Razman M.R.